How the heat transfer from one system to another? The one and only answer is Heat exchanger. So, what is heat Exchanger? What are the types of heat exchanger?

Here in this article you will get each of your answers with detailed explanation.

So, once again welcome to the wonderful and exiting world of engineering. Stay till end to know all about heat exchanger.

What is Heat Exchanger?

Table of Contents

A device which is used for transfering heat from fluid to another is called a “heat exchanger.” It is quite valuable as radiators which is used in automobile, intercoolers and pre heaters. Similarly, as condensers and boilers in steam plants. Also as condensers and evaporators in refrigeration, and air conditioning units.

Types of heat exchanger according to flow of fluid:

Before studying the type of heat exchanger, we should have a good understanding of the type of flow used in heat exchangers. Because different types of fluids are used in changing the temperature according to our requirement. This flow is parallel flow, counter flow and cross flow. In these three types of flow the relative direction of the hot and cold liquid changes only. The fluid may be separated by a jet wall or by a fixed tube called a double pipe.

• PARALLEL FLOW

If both fluids i.e. hot and cold fluids enter the heat exchange at the same end and run parallel to the outer end i.e. both fluids move in the same direction then it is known as “parallel flow.”

• COUNTER FLOW

When both the fluid enters into the heat exchangers at opposite direction but also moves parallel to each other then it is known as counter flow.

• CROSS FLOW

In this flow, both fluids flow at right angles to one another through the heat exchanger.

Types of heat exchanger according to the construction:

The different types of heat exchangers are classified mainly in 2 categories:

- Direct transfer type heat exchanger

- Direct Contact type heat exchanger

- Direct transfer type heat exchanger

These are also known as heat exchanger recuperators. Here the fluids are separated by a wall i.e. both hot and cold fluids do not mix. A wall can be a simple wall or tube or some other complex structure like fins and baffles. Surface heat exchangers with the most commonly used terminals for these heat exchangers can be constructed with large heat transfer volumes and are suitable for applications for heating, cooling, evaporation and condensation.

There are following heat exchangers which come in this category-

• Surface Condenser

• Economizer

• Air Preheater

• Shell and Tube Heat Exchanger

• Plate Heat Exchanger

• Plate and Shell Heat Exchanger.

• SURFACE CONDENSER

Surface condenser is a type of heat exchanger that is widely used in thermal power stations. These are water-cooled condensers that are installed when steam emits from a steam turbine.

It converts steam from its vapor state to its liquid state at a lower pressure than atmospheric pressure. The place where the cooling tower can’t be installed we prefer a surface condenser to that area. Sometimes the air also acts as a cooling fluid when the water supply is insufficient, but the cooling air condenser does not work very well because it cannot achieve the desired steam pressure and temperature at the exit.

Surface condensers have different applications in different industries where the same liquid circulates frequently by condensing and heating it.

• ECONOMISER

It is a mechanical tool used to reduce energy consumption by heating the liquid first before entering the boilers. It is a type of heat exchanger that is widely used in boilers, power plant and refrigerator as well as in air conditioning. In all these machines the economizer may differ in construction but the basic function is the same.

Economizer has several tubes through which a single liquid passes over the tubes. In the case of steam boilers the cooled fluid i.e. water passes through these tubes before entering the boiler and the hot flue gases which are released from the chimney flows over these tubes. As a result of which the incoming water temperature rises slightly before boiling. Thanks to the economizer we can save fuel consumption and save our process through waste heat.

• AIR PREHEATER

As the name suggests the use of air preheater is to pre-heat the air before further use to increase the thermal efficiency of the device. It is a type of heat exchanger. Heat loss due to the use of flue gas to preheat the air before entering the boiler in case of a thermal power station.

An air preheater heat exchanger is installed between the economizer and the chimney. This is a tubular structure. The Cold fresh air passing through tubes and hot gases passes through these tubes and then exchanges heat to warm the cold indoor air before entering the boiler.

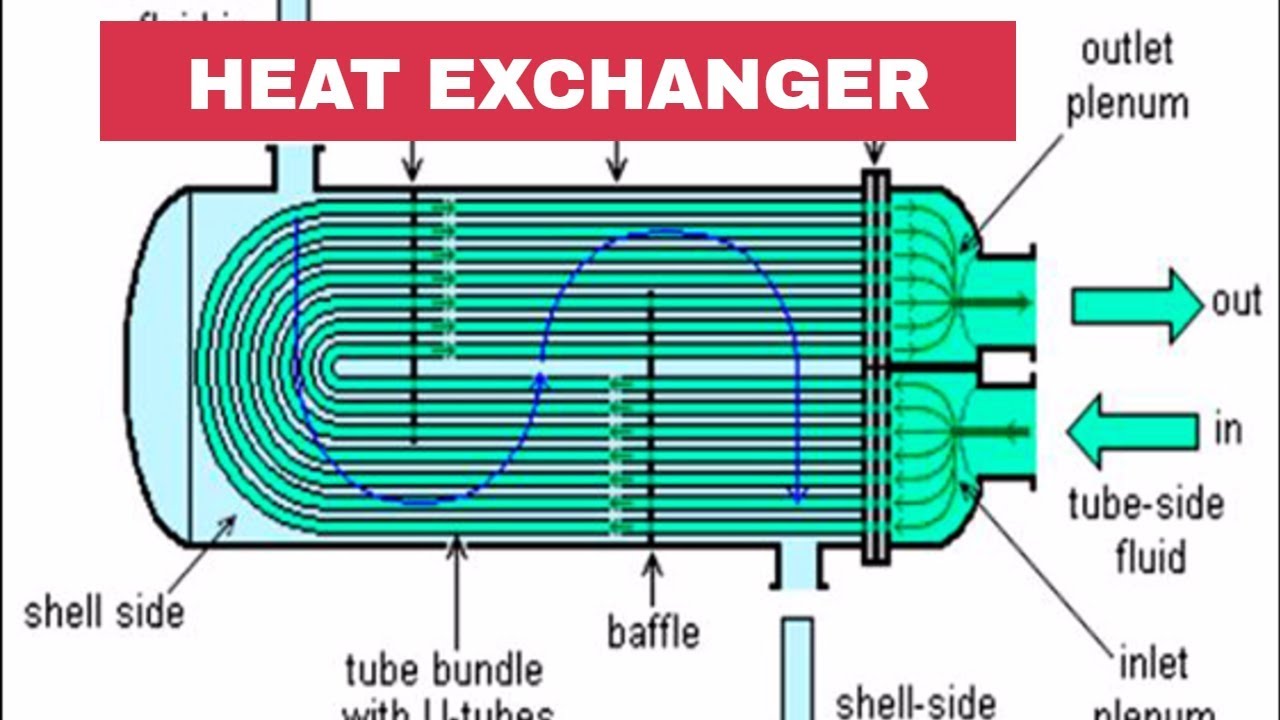

• SHELL AND TUBE HEAT EXCHANGER

Shell and Tube heat exchanger is used for high pressure applications. It generally operates at 30 bar pressure and temperatures above 260°C. It has a solid and durable structure to support high load and high pressure. It Contains a number of long-shelled tubes in the shell. Some fluids pass through these tubes and some fluids pass over them through the opening of the shells. All tubes are connected to a single inlet and a single outlet for the first liquid, this may be hot or cold. The second one passes through these tubes, baffles are supplied inside the shell to increase contact with the second liquid (flowing inside the shell) which has tubes.

The shell and tube have different shapes and designs but the basic function of all types is common. The diameter of the tube should be within the appropriate range. This should not too small and not too large, because small diameter tubes are difficult to clean dirt but small tubes make the heat exchanger economical and compact.

The baffle applied to the shell directs the flow of fluid into the tubes. They also prevent the tubes from eating. Different designs of baffles are used according to need. Baffles provide turbulence in the flow of fluid inside the shell resulting in a higher coefficient of high heat transfer to the outer tubes surface.

• PLATE HEAT EXCHANGERS

This is a kind of heat exchanger which consists of thin plates with an equal cross sectional area. These plates are separated by a very small distance. The surface area of these plates is quite large because the surface area dominates the heat transfer through these tubes. These plates are manufactured using gasket and brazing and are made of stainless steel. Due to the large area of the plates this heat exchanger works better compared to the shell and heat exchanger of the tube and is widely used in refrigeration systems.

Gasket directs streams between other plates and prevents external leaks. The gaskets are arranged so that each distribution flows smoothly between the other plates. The corners of all the plates have holes to pass through the liquid, to remove heat from the plates as the liquid flows through them. This is usually done periodically as needed.

• PLATE AND SHELL HEAT EXCANGER

It is a combination of both plates with both shell and heat exchange tubes. The plates are placed in a shell. A series of plates joined together for better heat transfer. These plates are made of stainless steel of some high-quality materials. These plates are hung directly on the shell. These plates are corrugated to provide support points to increase heat transfer.

The circular plates used are split and welded to fit the shell. This technology provides high heat transfer at high temperatures and pressures. Gaskets used here; this is a key advantage of plate and shell heat exchanger because it provides protection against leakage at high pressures and temperatures. A full pack of plates assembled into an outer shell that creates a second flow path on the side of the shell.

- Direct Contact type heat exchanger

In direct contact type heat exchanger both the hot liquid and the cold liquid combine together and the heat exchanges between them i.e. both the fluid comes in contact with the heat exchange.

The following are the main types of heat exchangers for the direct contact type-

• Cooling tower

• Jet condenser

• COOLING TOWER

A cooling tower is a type of heat exchanger where the hot liquid is cooled by a water spray. In this case both hot and cold liquids combine to form heat exchangers. Cooling tower is a type of heat rejection device that reacts to atmospheric heat even though water cooling flows at low temperatures.

The cooling tower uses the evaporation process to dissipate heat in hot liquid (water) and cool it at the wet bulb temperature or sometimes Air is used to cool the water at dry bulb temperature.

A cooling tower may have natural or induced draft depending on operating conditions. The cooling tower is used to cool most of the water so it re-calculates to work in a cycle. Cooling towers are used in many industries such as thermal power station, chemical industries, refineries etc.

• JET CONDENSER

Jet condenser is a type of direct contact with a liquid. In which both hot and cold liquids combine to heat up. In a jet condenser cooling water is pumped into the exhaust air through a jet out of the turbine. Due to this direct contact of steam and cooling water occurs and both are mixed. Then the steam starts to thicken, this thickening speed is very fast. Then the condensate can no longer be used as a feeder for boilers.

The temperature of the condensate is similar to that of cooling water leaving the condenser. Due to the additional mixing of the steam and the cooling water jet, condenser requires a small amount of cooling water to reach the steam. Jet condensers usually require less floor space because of this they are cheaper than any other type of condenser. Despite these advantages, jet condensers are rare in thermal power plants mainly due to condensate loss.

Conclusion: Heat exchanger

So, today we all have discussed each and every important types of heat exchanger. Hope this will help you a lot. We tried our best to give you the worthy results you came here for.

If this was helpful in your views, then do share this with your friends. If you have any queries or any suggestions, then comment us or simply contact us through email.

FAQ’s

Heat transfer takes place according to which of the following law?

Second law of thermodynamics

Which of the following is the rate of heat transfer unit?

Watt

On which of the following does convective heat transfer coefficient doesn’t depend?

Surface area

In liquids and gases, heat transmission is primarily caused by?

Convection

Which of the following is the unit of coefficient of radiant heat transfer?

Feed water heater

For a cylindrical rod with uniformly distributed heat sources, the thermal gradient at half the radius location will be?

One half

In counter flow heat exchangers between two fluids

Both the fluids at inlet are in their hottest state

Air can be best heated by steam in a heat exchanger of

Double pipe type with fins on air side

Which type of heat exchanger an automobile radiator is?

Cross flow type