INTRODUCTION

Table of Contents

Venturimeter is one of the most important and popular instrument used in mechanical engineering in the field of fluid mechanics and machinery. In this article you will get to know about what’s the real function of venturimeter, it’s parts, applications, advantages and disadvantages.

WHAT IS VENTURIMETER?

A venturimeter is a mechanical device used for measuring ‘rate of flow’ of a flowing liquid in a pipe. Here pressure energy is converted into kinetic energy and thus it works on the principle of Bernoulli. Venturimeter is invented by a American hydraulic Engineer CLEMANS HERCHEL.

It was then developed and named after the name of a Italian physicist GIOVANNI BATTISTA VENTURI.

PARTS OF VENTURIMETER

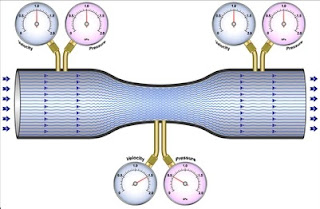

A venturimeter consists of three basic and major parts. A short converging cone, a throat and a long diverging cone. Let’s discuss every parts one by one in detail.

1. Short converging cone

It is the first part or portion of the venturimeter. It consists of short length decreasing cross section area tube. The liquid after passing through the pipe first enters the converging portion. Here in this portion pressure decreases and velocity increases due to decreasing cross section.

2. Throat

It is the middle part of the venturimeter. Its cross section area is constant. Thus the velocity and pressure remain constant throughout this cross section.

3. Long diverging cone

It is the last part of the venturimeter. Here in this portion the cross section area increases from start to end. Thus in this section pressure gets increase and velocity decreases.

NOTE:

(a.) The length of the divergent portion is kept longer than the convergent portion to minimize the chance of separation of the flow.

(b.) Normally the throat diameter is half or one third of the divergent tube diameter to avoid chance of cavitation.

WORKING PRINCIPLE OF VENTURIMETER

Since we all have already aware that the venturimeter works on the Bernoulli’s principle. Now we will try to understand how it happens.

See, it is well known to everyone that every fluid must have to follow continuity equation. Here in continuity equation discharge of liquid at inlet must be equal to discharge of liquid at outlet i.e. Q1= Q2 = A1V1 = A2V2.

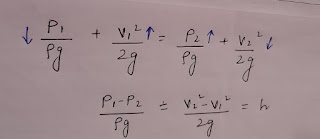

Here by the equation it is clear that the increment of area will lead to decrement of velocity or vice versa. Same situation is follow on venturimeter. Here in venturimeter, the liquid enters the convergent portion with normal pressure and velocity. But as soon as it passes through the convergent tube it’s velocity gets increases due to increased cross section area and thus by the increment in velocity, pressure gets decreased. See below Bernoulli’s equation for clarification:

Similarly when the liquid passes through the divergent portion it’s velocity gets decreased due to increasing cross section area. Thus by Bernoulli’s principle the pressure increases in this portion.

Thus we can easily say that the velocity is maximum and pressure is minimum at the throat of venturimeter.

ADVANTAGES OF VENTURIMETER

There are many advantages of a venturimeter. Below are the few of them:

1. Venturimeter is more accurate than any other flow rate measuring devices like orifice meter or rotameters.

2. It can be installed in any direction like horizontal, vertical or inclined. It will be give same reading in all directions.

3. Here coefficient of discharge is also high.

4. Power loss is comparatively low.

5. It can be also used where a small head is available.

6. It can be used for both compressible and incompressible fluid.

7. It is generally used for high flow rate.

DISADVANTAGES OF VENTURIMETER

Though venturimeter has many advantages but it has also some disadvantages which are given below:

1. The installation cost of venturimeter is comparatively higher than other.

2. It is quite expensive and bulky in practical.

3. This occupies more space as compare to other devices like orifice meter and pitot tube.

4. It’s maintenance is also quite difficult.

5. This device can’t be used for a small diameter pipe below 76 mm.

APPLICATIONS OF VENTURIMETER

There are many fields of operation of a venturimeter. Some are given below:

1. In most of the industrial plants it is used to measure the pressure and also the quantity of liquid and gas flowing through the large pipes.

2. These are widely used in waste treatment process where large diameter pipes are used.

3. It is also used for measuring the flow rate of the liquid that discharge through the pipe.

4. It has wide application in the medical field where it is used to measure flow rate of blood in arteries and veins.

5. Used for measurement of flow of chemicals in pipelines used in different industries like Indian oil, refineries, ongc etc.

That was all about venturimeter. It’s definition, parts, working principle, advantages, disadvantages and applications. Hope this will clear all you doubts and concepts. If you have any doubts then comment us below or feel free to contact us through email. If this article is helpful to you then share this with your friends.

Some images used in mechanical talks is taken from the licensed photo section of Google. We are not taking any kind of credit for all those images