Introduction

Table of Contents

As for your kind information, an I.C. engine consists of hundreds of different parts which are important for its proper functioning. To describe each and every part is little bit difficult. So, here in this article, we are going to discuss the basic and most important components of an I.C. engine which are very essential for the proper functioning of I.C. engine as well as for academic point of view.

The engine in which the combustion of fuel takes place inside the engine cylinder are called Internal combustion engine (I.C. engine).Here combustion itself gives power output. The working pressure and temperature inside the cylinder of an I.C. engine is very high.

Main parts of an Internal combustion engine:

1. CYLINDER

It is one of the most important component of the engine. In cylinder, the piston moves to and fro ( reciprocating motion ) in order to develop power. Generally the engine cylinder has to withstand very high pressure ( usually more than 50 bar ) and temperature ( more than 2000°C ). Due to which, the materials of an engine cylinder should be such that it can have sufficient strength to withstand at such kind of higher pressure and temperature. For simple or ordinary engines, the cylinder is made up of ordinary cast iron. But for heavy duty engines, it generally made up of steel alloys or aluminium alloys.

NOTE- In case of multiple cylinder engines, the cylinders are being cast in one block widely known as cylinder block.

Sometimes, a liner or sleeve is inserted into the cylinder which can be replaced after being worn out. Since the material required for liner is comparatively small, it can be made of alloy cast iron having long life and enough resistance to frequent wear and tear to the fast moving reciprocating parts.

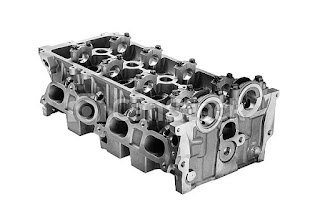

2. CYLINDER HEAD

It is fitted on one end of the cylinder and acts as a cover or safety to close the cylinder bore. It generally provides safeguard to the piston cylinder arrangement. Cylinder head consists of most important components such as inlet and outlet valves for admitting fresh charge and exhausting the burnt gases. In petrol engines, the cylinder head also contains spark plug for the ignition of fuel- air mixture, at the virtue of end of compression stroke. But in diesel engines, the cylinder head contains nozzle for injecting the fuel into the cylinder.

The cylinder head is usually cast as a one piece and bolted to one end of the cylinder.

Generally the cylinder block and cylinder head are made from same material. A copper or asbestos gasket is provided between the engine cylinder and cylinder head to make an air tight joint.

3. PISTON

It is considered as the heart of an I.C. engine, whose main function is to transmit the force exerted by the burning of charge to the connecting rod. The pistons are generally made of aluminium alloys which are mostly used for its light weight. Aluminium provides good heat conducting property and also much better and better sustainability at higher temperatures.

4. PISTON RINGS

These are circular rings and generally made of special steel alloys which retain their elastic property at higher temperatures. These piston rings are housed in the circumferential grooves provided on the outer surface of the piston. Generally there are two sets of rings mounted on the piston. The function of the upper rings is to provide air tight seal to prevent leakage of burnt gases into the lower portion. Similarly the function of the lower rings is to provide effective seal to prevent leakage of the oil into the engine cylinder.

5. CONNECTING ROD

It is a link between the piston and crankshaft, whose main function is to transmit force from the piston to the crankshaft. Further more, it converts reciprocating motion of the piston into rotational motion to the crankshaft, in the working stroke. The upper ( smaller ) end of the connecting rod is fitted to the piston and the lower ( bigger ) end is fitted to the crank.

The connecting rod are generally manufactured by the special steel alloys or aluminium alloys. The connecting rod should be cared very carefully while designing and manufacturing since it continuosly subjected to compressive or tensile stresses combined with bending stress.

6. CRANKSHAFT

It is considered at the backbone of an I.C. engine whose function is to convert the the reciprocating motion of the piston into the rotary motion with the help of connecting rod. This shaft contains one or more eccentric portions called cranks. That part of the crank to which the bigger end of the connecting rod is fitted, is called crank pin

It has been experienced that too many main bearings create difficulties for the correct alignment. Generally cast iron were used for the manufacturing of crankshaft in earlier days but now a days special steel alloys are used for the manufacturing of crankshaft. A special care is required for the design and manufacture of crankshaft.

7. CRANKCASE

It is a cast iron case which holds and stick the cylinder and crankshaft of an I.C. engine together. It also works as the sump for the lubricating oil. The lower portion of the crankcase is known as bed plate, which is fixed with the assistance of bolts.

8. GUDGEON PIN OR PISTON PIN

These are the hardened steel parallel spindles fitted through the piston bosses and the small end bushes or eye to allow the connecting rod to swivel. Its main function is to connect the piston to the connecting rod. It generally made hollow from inside for light duty.

9. VALVES

For the proper functioning of inlet and exhaust of the internal combustion engine valves are used. The number of valves depends upon number of cylinder used in internal combustion engine. Each cylinder consists of two valves i.e. inlet and outlet valve. Inlet valves are used for entry of air – fuel mixture in the cylinder and outlet valves are used for the exhaust of combustion or burnt out gases. Both these valves are usually open inward.

Note:

(a) Inlet valves are generally made of silicon chrome steel by the forging process.

(b) Outlet valves are made of Austenitic steel and also manufactured by forging process.

10. CAMSHAFT

For the proper timings of opening and closure of the valves the camshaft are came into use in internal combustion engine. For the efficient and proper productivity and output the inlet valve should be open at the end of the exhaust stroke and it in the same manner is should be closed at the end of suction stroke. A cam used in internal combustion engine is generally oval in shape. For the regulation of the valve timings it’s function becomes vital. It exert pressure for the closure and released it to open. It generally placed at top of the cylinder.

10. SPARK PLUG

It is used in spark ignition engine (S.I. engine) or petrol engines. The main function of a spark plug is to conduct a high potential from the ignition system into the combustion chamber to ignite the compressed air fuel mixture. It is fitted on cylinder head. The spark plug consists of a metal shell having two electrodes which are insulated from each other with an air gap. When high potential current supply to spark plug it jumping from the supply electrode and produces the necessary spark. It plays one of the most vital role in S.I. engine.

11. INJECTOR

Injectors are usually used in compression ignition engine ( C.I. engine ) or diesel engines. It sprays the fuel into combustion chamber at the end of compression stroke. It is fitted on cylinder head.

12. MANIFOLD

Its main function is to supply the air fuel mixture and collects the exhaust gases equally from all cylinder. In an internal combustion engine two manifold are used, one for intake and other for exhaust. They are usually made by aluminum alloys for the light duty operations.

13. PUSH ROD

Pushrods are used when the camshaft is situated at the bottom end of cylinder.

It carries the camshaft motion to the valves which are situated at the cylinder head.

14. FLYWHEEL

Flywheel is big wheel, mounted on the crankshaft whose function is to maintain its speed constant. This is done by storing excess energy during power or expansion stroke.

That was all about the main parts of an internal combustion engine and their functions. If you like this article, please do share it with your well wishers. If you have any doubts please let us know in comment section or contact us through email.

Some images used in mechanical talks is taken from the licensed photo section of Google. We are not taking any kind of credit for all those images.