Important terms used in gears

Table of Contents

As per the rule of the nature, every single thing which is in existence must have a name to be known to everyone. The term which identify or illustrate the meaning of anything is called ‘Terminology’.

Here in this article, we have discussed about the different different terms used in gears.

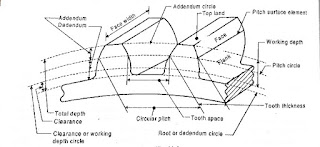

The different terms used in gears are discussed below with explanation :

1. Pitch circle

Pitch circle is an imaginary circle of the gear where pure rolling motion is observed without slipping, when the mating gears transmit power.

2. Pitch circle diameter

The measure of the diameter of the pitch circle is called pitch circle diameter. The size of the gear is generally specified by pitch circle diameter. Sometimes it is called pitch diameter.

3. Pitch point

Pitch point is the common point of contact between two pitch circles. It plays an important role in the law of Gearing.

It is also key defining term of pressure angle.

4. Pitch surface

It is the surface of the rolling discs which is replaced by the meshing gears at the pitch circle.

5. Pressure angle or angle of obliquity

It is the angle between common normal of two gear teeth at the point of contact and the common tangent at the pitch point.

Or

It is the angle between line of action which is normal to the point of contact and common tangent at the pitch point.

It is usually denoted by Φ

The value of pressure angle lies between 14° to 22°.

6. Addendum

Addendum is the radial distance of a tooth from the pitch circle to the top of the tooth.

7. Dedendum

Dedendum is the radial distance of a tooth from the pitch circle to the bottom of the tooth.

8. Addendum circle

It is the circle drawn through the top of the teeth and is concentric with the pitch circle.

9. Dedendum circle

It is the circle drawn through the bottom of the teeth. It is also called root circle.

NOTE: Root circle diameter = pitch circle diameter × cosΦ, where Φ is the pressure angle.

10. Circular pitch

It is the distance measured on the circumference of the pitch circle from a point of one tooth to the corresponding point on the next tooth. It is usually denoted by Pc. Mathematically,

Pc = π D/ T

Where Pc – diameter of the pitch circle

T – number of teeth on the wheel.

Looking further more, we can understand that the two gears will mesh together correctly if the two wheels have the same circular pitch.

NOTE: If D1 and D2 are the diameters of the two meshing gears having teeth T1 and T2 respectively, then for them to mesh correctly,

Pc = πD1/ T1 = πD2/ T2

Or D1/D2 = T1/T2

11. Module

It is the ratio of pitch circle diameter millimetres to the number of teeth. It is generally denoted by m. Mathematically,

m = D/T

NOTE: module = Addendum

12. Diametral pitch

It is inversely proportional to the module i.e. it is the ratio of number of teeth to the pitch circle diameter in millimetres. It is denoted by Pd. Mathematically,

Pd = T/D = π/ Pc

13. Clearance

It the radial distance from the top of the tooth to the bottom of the tooth in a mating gear. A circle passing through the top of the mating gear is known as clearance circle.

14. Tooth thickness

It is the width or thickness of the tooth measured along the pitch circle.

15. Tooth space

It is the width of space between two consecutive teeth measured along pitch circle.

16. Backlash

It is the difference between the tooth space and the tooth thickness. It measures along the pitch circle. As in the manufacturing of the gear it is desirable to keep the backlash as close to zero but in actual practice some amount of backlash is provided to prevent jamming of the teeth because of the thermal expansion or tooth errors.

17. Working depth

It is the radial distance from the addendum circle to the clearance circle. It is equal to the sum of the addendum of the two mating gears.

18. Total depth

It is the radial distance between the addendum and dedendum circles of a gear. In simple terms, it is equal to the sum of addendum and dedendum.

19. Face

Face is the portion of the gear tooth profile above the pitch surface.

20. Flank

Flank is the portion of the gear tooth profile below the pitch surface.

21. Profile

It is the curvature contained by the face and flank of the gear tooth.

22. Path of contact

It is the path travelled by the point of contact of two teeth from the starting of the engagement to the end of the engagement.

Path of contact = Path of approach + Path of recess

23. Length of path of contact

It is the length of the common normal cut – off by the addendum circles of the wheel and pinion.

24. Arc of contact

It is the path traced by a point on the pitch circle from the starting of the engagement to the end of the engagement for a given pair of teeth.

Arc of contact = path of contact/ cos@

Arc of contact also consists of two parts :

A.) Arc of approach – It is the portion of the path of contact from the starting of the engagement to the pitch point.

B.) Arc of recess – It is the portion of the path of contact from the pitch point to the end of the engagement of a pair of teeth.

Arc of contact = Arc of approach + Arc of recess

25. Contact ratio

It is the ratio of length of arc of contact to the circular pitch. It is the denotation of number of pairs of teeth engaged in one contact.

That was all about the important terms used in gears in automobile. Hope you all like this article. If this was helpful to you then share this article with your well wishers. If you have any doubts regarding this or any mechanical engineering topics then let us know in comment section or contact us through email.