Gas Turbines

Table of Contents

In a gas turbine, first of all, the air is obtained from the atmosphere and compressed in an air compressor. The compressed air is then passed into the combustion chamber, where it is heated considerably. The hot air is then made to flow over the moving blades of the gas turbine, which imparts rotational motion to the runner. During this process, the air gets expanded and finally it is exhaused into the atmosphere. A major part of the power developed by the turbine is consumed for driving the compressor. The remaining power is utilised for doing some external work.

Important features of a gas turbine

• Gas turbine worked on Baryton cycle.

• It consists of two reversible adiabatic and two isobaric process.

• The four main components of a gas turbine consist of compressor, combustion chamber, turbine and cooling media (chamber).

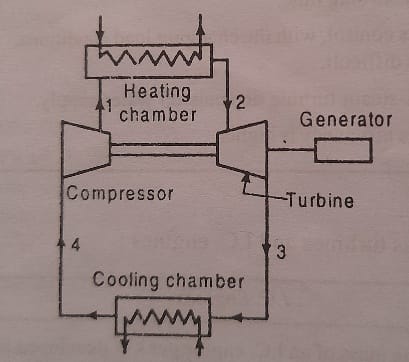

• Here the process 1-2 is known as reversible adiabatic compression process which is done by compressor.

• Process to 2-3 e is known as isobaric heat addition process which is done by combustion chamber.

• Process 3-4 is known as reversible adiabatic expansion process which is done by turbine.

• And process 4-1 is called as isobaric heat rejection process which is done by cooling media (chamber).

Classification of Gas Turbines

The gas turbines may be classified as followy types:

- According to the path of the working substance

(a) Closed cycle gas turbines

(b) Open cycle gas turbines

(c) Semi-closed gas turbines.

- According to the process of heat absorption

(a) Constant pressure gas turbines

(b) Constant volume gas turbines.

CLOSED CYCLE GAS TURBINES

A closed cycle gas turbine, in its simplest form, consists of a compressor, heating chamber, gas turbine which drives the generator and compressor and a cooling chamber. It works on Joule’s or Brayton’s cycle. The air is heated in a heating chamber at constant pressure and expanded isentropically in the turbine. Similarly, the air is cooled in the cooling chamber at contant pressure and compressed isentropically in the compressor.

OPEN CYCLE GAS TURBINES

An open cycle gas turbine is also consists of a compressor, combustion chamber and a gas turbine which drives the generator and compressor as shown in the figure given below.

In an open cycle, the gases coming out from the gas turbine is exhausted in the atmosphere.

Since the combustion of the fuel takes place continuously, therefore this turbine is also called ‘continuous combustion gas turbine’. This turbine also works on Joules cycle or Brayton cycle.

Applications of a Gas Turbines

The gas turbines are mainly used where the high power and speed are the primary consider ations. The applications of gas turbines are as follows:

- It is widely used in jet propulsion unit for air craft.

- It can be used in ships as the propulsion unit.

- It is used in the electric generating stations and in locomotives.

- It is used in the process of supercharging.

So, that was the explanation about gas turbines, its classification and applications. Hope you all like this information. Do subscribe our website and turn on notification, so that whenever there is any content available, it will get to you instantly. Also, do share this with your mates.

FAQ’s-

Q.A closed cycle gas turbine is works on ?

Brayton cycle or Joule cycle

Q. The compression ratio in a gas turbine is ?

7

Q. The maximum temperature in a gas turbine is ?

700°C

Q. The ratio of net work obtained from the gas turbine to turbine work is known as ?

Work ratio

Q. High air fuel ratio in gas turbine ?

Reduces exhaust pressure

Q. In a closed cycle gas turbine, the air is compressed ?

Isentropically

Q. The gas in cooling chamber of a closed cycle gas turbine is cooled at ?

Contant pressure

Q. Gas turbine power plant is __ efficient than steam turbine plant

More

Q. Maximum combustion pressure in a gas turbine is _ as compared to diesel engine

Less

Q. Efficiency of a gas turbine can be increased by ?

Regeneration

Good notes