Today, once again we are going through the different types of boilers and this time its Cornish Boiler. We will see Cornish Boiler: Introduction, Components, Working, Applications, Advantages (Notes with PDF).

So, read the full detailed explanation and you will get to know each and every aspect of Cornish Boiler.

What is a Cornish Boiler?

Table of Contents

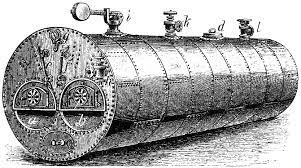

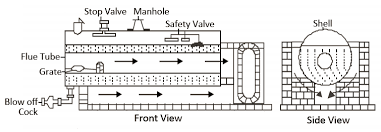

The Cornish boiler is a horizontal fire boiler with an internal fire tube. Cornish boilers were first manufactured in 1812 by Richard Trevithick. Cornish boilers have a long horizontal shell cylinder. This boiler has only one fire clock running from front to back.

This fire clock is not centered inside the shell. This is removed from the fire station. This firetube is removed from the center because the shell is not completely filled with water, some part of the upper part of the shell is left to explode, and the firetube is positioned almost in the middle of the water- full area.

For Cornish boilers, the shell has a length of 5 to 7 meters, and it’s diameter is 1.25 to 1.75 meters.

Components of Cornish Boiler:

- The shell

The shell has water and a tube. Heat transfer in water occurs in the shell. And the shell is such that it covers all the parts of the boiler and is also called the main body.

- Grate and furnace

This is a place in the fireplace where coal will be stored and burned. A furnace is a place where coal or fuel enters and burns within it. Grate is the part where heat is developed with the help of fuel combustion.

- Furnace

The furnace acts as an mediator Because it is connected between the fire hose and the combustion chamber. Here the fuel burns and produces heat.

- Combustion chamber

Here the fuel burns in the combustion chamber and produces the heat supplied to the tube. Here, the water is condensed. The combustion chambers are connected to the furnace.

- Ash pit

The fuel ash here is completely burnt and does not work inside the boiler.

- Chimney

The chimney is here to release gases into the air.

- Smokebox

A Smokebox is provided here to collect the smoke and send it to the chimney.

- Water level indicator

It is a device that determines the amount of water in a boiler. This applies even when the water is above the limit, or the water below the limit.

- Safety valve

The safety valve is a type of metal, used for safety purposes, and works even when no other indicator is in place.

- Man Hole

This is a man hole from which the any person or specially engineers will enter and replace when any components will damage inside the boiler.

- Stop Valve

Stop valves are also used to completely shut off the flow when required.

- Blow off valve

Blow off valve is used to clean the boiler by removing water and sediment from the bottom of the boiler.

Cornish Boiler Operating System:

• The thing that works here is coal. In the furnace, the fuel is supplied, which is coal, and sent to the furnace. Here we burn fuel by providing a certain amount of fire. So as we know, it’s a big tube boiler.

• Coal burning produces heat that is sent to the pipe, and water is distributed here. Why is the water surrounded by itself? Because we supply water here and use a tool, a water level indicator, we measure the water level.

• So now there is so much heat in the tube that the water begins to heat up, which means that the water first converts into a full steam, then heats up and converts it into a hot steam now in operation. Steam can be used for a variety of purposes.

• Meanwhile, the burning coals here fall into the ash pit, and from here, they smoke, and the gas will leave the chimney in the surrounding area. And we get the ashes out of the system and clean it up.

Construction of Cornish Boiler:

• The shortest part of the boiler is the outer shell of the long cylinder. It is the most outdoor part of Cornish boilers, which contains other parts of the boiler. Inside the shell is an internal fire pipe near the bottom of the boiler.

• The fire clock is set in the center of the Cornish boiler water area. The furnace and the furnace are on the front side of the boiler. The coal is prepared for grinding in a fire pit. A brick arc is also provided to prevent burning coal ash from entering the fire pipe and flue tube.

• Two flue tubes are located on both sides of the boiler and are called side flue, and one is introduced into the bottom of the boiler and is known as the lower flute. There is another catch tube called the main grip tube.

• With these main flue tubes, the flue gases reach the chimney. This chimney is used to transfer gases and fumes into the atmosphere from the flu flu. Apart from these parts, other mountings are installed in the boiler.

• The spring-loaded safety valve is fitted to the boiler to relieve pressure of excess steam whenever there is excessive steam pressure inside the boiler. There is another inlet shut-off valve and it is used to control the smoke produced between the smoke pipes, and the boiler is located at the top of the boiler.

• Low-Scale Water Safety Valve The stool is also provided near the valve and is used to release the steam produced when the water level falls below a certain level. There is a water supply pipe inside the boiler to fill the water.

• This feed pipe is controlled by a feed valve. The steam produced inside the boiler contains a large amount of water in steam areas and is called priming. An anti-accuracy pipe is provided to separate the water as much as possible. Blow-off coke is used to remove mud inside the boiler floor.

• This explosive rooster can be used as a stimulant to completely drain water from the boiler. A large hole is also available, which is used for inspection inside the boiler.

Applications of Cornish Boiler:

• Cornish boilers are used in many industries such as sugar, paper, tires, chemicals, etc.

• Cornish boilers are also used to produce steam using steam engines.

• It is also found in many marine industries.

Advantages of Cornish Boiler:

• Cornish boilers have a very simple design and easy construction.

• It is a compact and portable boiler.

• This can overcome load fluctuations during boiler operation.

• The production and storage costs for this boiler are very low.

Disadvantages Cornish Boiler :

• The minimum steam generation rate is about 1350 kg / h.

• It can take a maximum steam pressure of 10.5 bar.

• The horizontal structure needs more soil.

So, thats all from today’s article. Hope you all like this information. If this was helpful to you then kindly share this article. Stay tuned with us for more mechanical engineering stuffs.

You May also read this – Locomotive Boiler: Definition, Working Principle, Components, Advantages and Applications (Notes with PDF)

FAQ’s

How many flue tubes are there in Cornish boiler?

1

The diameter of the Cornish Boiler varies from

1 to 2 m

The length of the Cornish Boiler varies from

5 to 7.5 m

The maximum steam pressure of a Cornish Boiler is

10.5 bar

What are applications of a Cornish Boiler?

Cornish boilers are used in many industries such as sugar, paper, tires, chemicals, etc.