In the engineering field of machinery and waters, we are here with Reciprocating Pump: Introduction, Components, Types, Working principle, Applications (Notes with PDF).

Here in this article, we will discuss each and every aspect of Reciprocating pump.

So, read the full article and have some great ideas and knowledge.

Definition of Reciprocating Pump

Table of Contents

A reciprocating pump is a device that converts mechanical energy into hydraulic energy by absorbing fluid into a cylinder. In this Pump system, the piston reciprocates using the liquid-push and increasing its hydraulic power/energy.

A reciprocating pump is also known as a positive displacement pump. Because it releases a fixed quantity of liquid. It is usually used when a small amount of fluid is to be treated and when the delivery pressure is very high.

Components of Pump Reciprocating

The following are the main components of a repeat pump:

• Cylinder

• Suction Pipe

• Delivery Pipe

• Suction valve

• Delivery valve

• Air vessels

• Cylinder

Cylinder, where the piston moves from side to side. The piston time is obtained by the connecting rod, which connects the piston to the crank.

• Suction pipe

When the water source connects the cylinder together. The suction pipe allows water to flow into the cylinder.

Delivery Pipe

After the procedure, the water source leaves the cylinder and flows through the delivery pipe.

Suction Valve

In this valve, water flows in from the suction pipe to the cylinder.

Delivery Valve

In this valve, water flows from the cylinder to the delivery pipe.

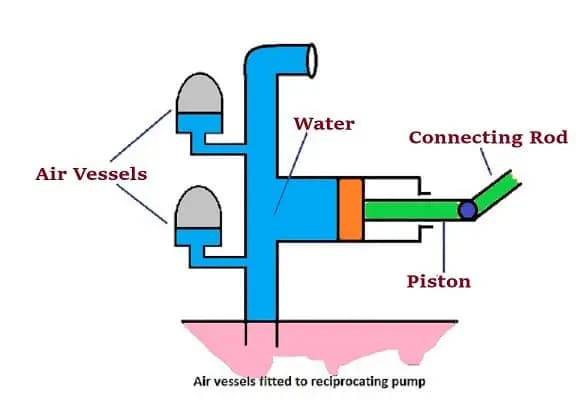

Air Vessels

It is a closed room cum chamber made of cast iron material. Having two sides, one end is open at its base where the water flows into the cylinder portion. The air vessels are fitted with a suction pipe and a delivery pipe for this pump to achieve a uniform discharge throughout.

It also avoids the interruption of flow.

Types of reciprocating pump

The following are the types of reciprocating pumps depending on the source of the operation and method:

• Simple hand-operated reciprocating pump

• Power-operated deep well reciprocating pump

• Single-acting reciprocating pump

• Double-acting reciprocating pump

• Triple-acting reciprocating pump

• Pump with air vessels

• Pump without air vessels

Working principle of Reciprocating pump

The working of a reciprocating pump mainly depends upon the number of valves (procedure routes) used for the circulation of liquid.

Thus it is mainly divided into two parts:

- Single Acting Reciprocating Pump

• In this case, the Cylinder, where the piston moves forward and backward. The piston reciprocates using a connecting rod. The connecting rod connects the piston and the rotating crank. The crank rotates with an electric motor.

• The suction valve allows water to the cylinder. Similarly the delivery valve leaves water in the cylinder.

• As the crank rotates, during the first piston stroke (called suction stroke), water enters the cylinder. In the suction stroke, the crank rotates from 0 ° to 180 °as the piston moves to the right side of the cylinder. As a result, the vacuum creates a cylinder. This vacuum causes the suction valve to open and water to enter the cylinder.

• In the next stage called delivery stroke, water leaves the cylinder. In the delivery stroke, the crank rotates from 180 ° to 360° with the piston moving to the left side of the cylinder. As a result, the pressure of the liquid increases inside the cylinder. This pressure causes the suction valve to close and the delivery valve to open. The water is then forced into the delivery pipe and raised to the required height.

- Double Acting Reciprocating Pump

Here in this system, the water is acting on both sides of the piston. Therefore 2 suction pipes and 2 delivery pipes are required for a Double Acting Reciprocating Pump. When there is a suction stroke on one side of the piston, at the same time there is a delivery stroke on the other side of the piston.

So, with one complete turn of the crank, there are two delivery stroke and water is brought to the pipes by pump during these two delivery strokes.

Applications of Reciprocating Pump

• A reciprocating pump is used in oil drilling operations.

• It is useful for pneumatic pressure systems.

• It is widely used in pumping small amounts of oil.

• Used to feed small boilers return condensate.

• It is very beneficial where highly pressurized liquid is required.

So, that was all from today’s article. We have learnt plenty of things about Reciprocating Pump: Introduction, Components, Types, Working principle, Applications (Notes with PDF). Hope you all like this information.

Stay tuned with us for more mechanical engineering stuffs like this.

You may also read – Centrifugal pump: Introduction, components, multistaging, heads and applications.

FAQ’s

Q. Reciprocating pump is a

Positive displacement pump

Q. What happens to the reciprocating pump when left untouched?

Surface expansion

Q. The cylinder of reciprocating cylinder is made up of

Cast iron

Q. The higher discharge valve line holds the discharge valve

Closed

Q. Reciprocating pumps are also called as

Force pumps

Q. Reciprocating pumps are classified according to

Number of cylinders

Q. Internal cavitation in reciprocating pumps occurs due to

Shock waves

Q. Power operated pump in which only one side engages the fluid displacement is called

Single Acting Reciprocating Pump

Q. An up and down back and forth relative linear motion is called

Reciprocation

Q. Bicycle pump generates more compression than volume displacement?

True